Kuwait, known for its oil-driven economy, is rapidly embracing innovation to diversify and strengthen its industrial base. One of the most trans formative developments in recent years is the integration of robotics automation into the country’s manufacturing processes. This shift is not just a technological upgrade but a strategic move to enhance productivity, reduce costs, and ensure high-quality outputs. As industries around the world adopt advanced robotics, Kuwait is stepping forward to remain competitive and future-ready.

The Rise of Robotics in Kuwait’s Industrial Landscape

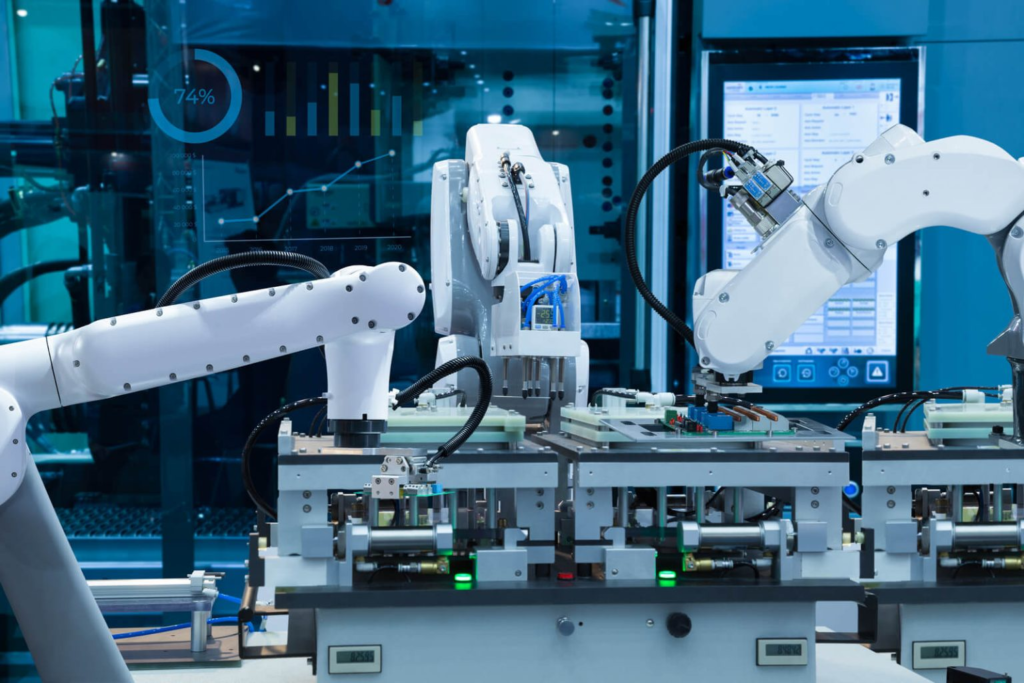

Robotics automation is no longer a distant dream; it is becoming a reality across many sectors in Kuwait. Manufacturers are increasingly using automated robots for tasks ranging from assembly and welding to packaging and quality control. This adoption stems from the need to improve efficiency while reducing reliance on manual labour for repetitive and hazardous tasks. Kuwaiti industries, particularly in petrochemicals, food production, and electronics, are actively investing in robotic solutions to meet growing demands and international standards.

Why Robotics Automation Matters for Kuwait

The benefits of robotics automation extend far beyond increased production speed. For Kuwait, the introduction of robotics ensures precision, consistency, and reduced operational errors. It minimises downtime, lowers production costs, and significantly improves safety by keeping human workers away from dangerous environments. Moreover, automation supports sustainable practices by optimising resource use and reducing waste. These advantages help Kuwait position itself as a hub for high-quality manufacturing in the Middle East.

Driving Innovation with Advanced Technology

Kuwait’s manufacturing sector is not just adopting robots; it is embracing an entire ecosystem of advanced technologies. From collaborative robots (coots) that work alongside humans to AI-powered automation systems that analyse data in real time, innovation is at the core of this transformation. Many companies are integrating Internet of Things (IoT) devices to monitor machine performance and predictive maintenance, ensuring smooth operations. This integration of robotics with AI and IoT paves the way for smarter factories that can adapt to market changes quickly.

Boosting Workforce Productivity and Skills

While there is often concern that robots may replace human jobs, Kuwait is witnessing a different outcome. Robotics automation is helping workers shift from mundane, repetitive tasks to more strategic and creative roles. Employees are being trained to manage, program, and maintain these robots, resulting in skill enhancement and career growth. The government and private organisations are also investing in training programs to prepare the workforce for Industry 4.0, where humans and machines work hand in hand to achieve excellence.

Enhancing Product Quality and Global Competitiveness

For manufacturers in Kuwait, delivering world-class products is a priority. Robotics automation plays a critical role in maintaining high quality standards. Robots execute tasks with precision, minimising defects and ensuring uniformity across every production batch. This level of consistency enhances the global reputation of Kuwaiti products, opening doors to international markets and partnerships. By adopting automation, Kuwait is not only improving local industries but also strengthening its position in the global manufacturing arena.

Cost Efficiency and Long-Term Returns

Implementing robotics may seem expensive initially, but the long-term benefits are remarkable. Reduced labour costs, minimised material waste, and fewer production errors lead to significant savings over time. Automated systems work round the clock without fatigue, increasing overall output without proportionally increasing costs. This cost efficiency allows manufacturers to reinvest in innovation, research, and development, further fuelling industrial growth.

Sustainability Through Automation

Environmental sustainability is an emerging priority worldwide, and Kuwait is no exception. Robotics automation helps industries adopt greener practices by optimising energy use, reducing emissions, and lowering waste generation. Robots precisely manage resources, ensuring minimal environmental impact while meeting production targets. This aligns with Kuwait’s vision to balance economic growth with environmental responsibility, contributing to a more sustainable future.

Challenges in Adopting Robotics Automation

Despite its many advantages, the transition to robotics automation is not without challenges. High initial investment costs, the need for skilled personnel, and resistance to change can slow down adoption. Small and medium-sized enterprises (SMEs) may find it difficult to implement expensive technologies. However, with government support, partnerships, and gradual integration, these challenges can be overcome. Continuous training and awareness programs are essential to ensure a smooth shift toward automated manufacturing.

Future of Robotics in Kuwait’s Manufacturing

The future looks promising for robotics automation in Kuwait. As more industries embrace automation, we can expect smarter, more efficient, and highly adaptive manufacturing environments. The combination of robotics with artificial intelligence, machine learning, and cloud computing will enable factories to predict market demands, optimise production lines, and deliver customised products at scale. This innovation-driven approach will make Kuwait a leader in modern manufacturing across the region.

Conclusion

Robotics automation is redefining the way Kuwait manufactures products, offering unparalleled benefits in efficiency, quality, and sustainability. By investing in advanced technology, fostering a skilled workforce, and embracing innovation, Kuwait is paving the way for an industrial revolution that goes beyond oil dependency. As the country continues to adopt and evolve with these advancements, its manufacturing sector will not only thrive locally but also gain a competitive edge globally. Robotics is not just streamlining processes it is shaping the future of Kuwait’s industrial success.

Do follow Gulf Magazine on Instagram.

Also Read – How Wearable Devices Are Powerfully Transforming Fitness Culture in Kuwait