Oman is experiencing a trans formative wave in its construction sector through the rapid integration of 3D printing technology. This modern approach is reshaping the way buildings are designed and constructed delivering speed efficiency sustainability and design flexibility in a way that feels profoundly human. As local innovators academics developers and government authorities embrace this change the construction landscape in Oman is redefining itself into something faster smarter more efficient and deeply centered on human needs and community well being.

What Is 3D Printing in Construction

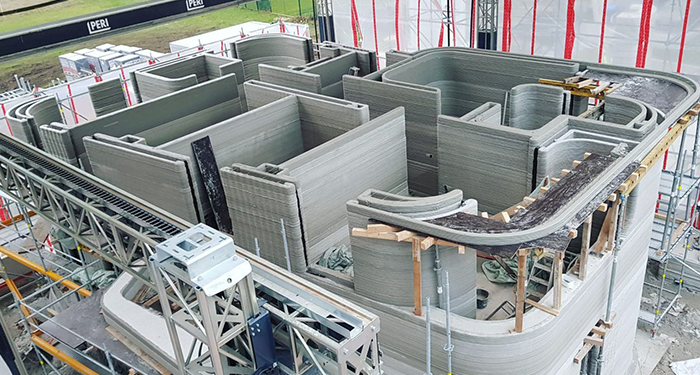

3D printing in construction also referred to as additive manufacturing uses large scale printers that build structures by layering concrete mortar or composite materials. Instead of traditional formwork scaffolding and manual brickwork the printer deposits precise material sequentially resulting in walls components or even whole buildings. This method eliminates guesswork speeds construction and reduces waste creating a leaner more resource conscious process.

How Oman Is Embracing 3D Printing

Omani construction firms are partnering with global additive manufacturing technology providers and local research institutions to launch pilot projects across the Sultanate. These partnerships focus on prototyping affordable housing community centers and architectural showcases in both urban and rural regions. Local universities and material science institutions test mixes suited to Oman’s arid hot climate using indigenous aggregates gypsum blends and low cement mixtures adapted for extrusion processes. This homegrown experimentation ensures the technology is tailored to local conditions strengthening national innovation capacity while accelerating adoption across the sector.

Unmatched Speed and Operational Efficiency

One of the most compelling advantages of 3D printing in construction is the speed of delivery. Traditional building methods often require weeks or months of preparation onsite form work curing and manual labor. In contrast with 3D printing the shell of a building can be printed in only days. This speed drastically reduces project timelines decreases financing costs and causes minimal disruption to communities especially in fast developing urban areas or remote growth towns. Developers in Oman are already reporting that projects which once took months to complete are now finalised in a fraction of that time thanks to additive manufacturing.

Significant Cost Savings and Waste Reduction

3D printing enables precise material usage because only the exact quantity needed is deposited layer by layer. This eliminates over ordering and onsite waste common to traditional building methods. With fewer workers needed for repetitive physical tasks developers reduce labour costs while maintaining quality consistency. Especially in a market like Oman where many building materials are imported or expensive locally minimising waste improves financial viability and sustainability. Cost per square meter declines making affordable housing and community infrastructure more viable for both public and private stakeholders.

Promoting Sustainable Construction Practices

Oman is deeply invested in sustainability goals supported by Vision 2040 and environmental commitments. 3D printing aligns with these goals by using optimised mixes that reduce cement demand incorporate recycled materials and minimise dust emission noise and site disturbance. In desert environments this reduced footprint is particularly valuable helping preserve local ecology and protect community health. Additionally printed structures often require less energy in curing and trimming further reducing carbon emissions associated with conventional construction methods.

Design Innovation and Architectural Freedom

Traditional construction often limits design possibilities due to structural constraints form work limitations and labour intensive finishing. 3D printing breaks these barriers offering fluid organic curved forms intricate façades and free form geometries that would be prohibitively complex or expensive using conventional means. In Oman this opens doors to architecture inspired by local heritage using motifs vaulted shapes sand dune inspired curves and bespoke textures that celebrate Omani identity while embracing modern form. Communities gain access to creative environments that inspire pride and authenticity.

Enhanced Worker Safety and Wellbeing

Conventional construction involves risky tasks including working at heights heavy manual handling dusty conditions and exposure to heat. 3D printing significantly reduces onsite labour especially for hazardous processes. Printers operate in more controlled environments with fewer individuals exposed to risk. Workers transition to simulator or control roles feeding machines monitoring material performance or maintaining robotics. This pivot increases safety reduces injury potential and elevates skills training empowering a modern workforce aligned with emerging technologies.

Pilot Projects Highlighting Success in Oman

Across Oman early initiatives demonstrate real world benefits. One residential pilot project features small affordable housing units built using printed core structural walls later fitted with conventional finishes. These units were completed in record time at lower cost while satisfying thermal insulation standards suited to desert conditions. Another example from campus development saw a small community pavilion printed in under a week showcasing curved forms and sustainable material mixes. Commercial kiosk prototypes at public parks are also using modular printed sections reducing setup time and demonstrating flexibility. These localised projects provide vital data on local thermal performance curing adaptations material behaviour and cost models calibrated for Omani conditions.

Academic Research and Material Innovation

Local universities research centres and industry partners are working to adapt 3D printing to Omani climate and resources. Trials involve blends of locally sourced sand gypsum and pozzolans that optimise extrusion performance while maintaining strength. These experiments are conducted under extreme heat and humidity to ensure durability resilience and long term stability. Testing covers mechanical strength thermal conductivity weather resistance and compatibility with finishes. Findings are informing local standards and encouraging Omani engineers to enter additive manufacturing certification programs strengthening technical capacity in country.

Regulatory Evolution and Quality Assurance

As 3D printed structures become more prevalent Oman’s regulatory framework is evolving in parallel. Authorities are drafting building code updates tailored to additive manufacturing covering structural integrity mix specifications curing protocols and inspection procedures. Quality control guidelines are being developed to ensure that printed elements meet safety criteria. Pilot projects serve as test beds for these guidelines informing revisions to national standards regulatory approvals and approvals by safety inspectors. This regulatory foresight helps ensure that printed buildings are as safe reliable and robust as conventional ones.

Addressing Challenges Effectively

Despite tremendous promise additive manufacturing in construction faces challenges. Oman’s hot and dry climate can affect curing rates cracking and material shrinkage. Ensuring consistent quality across prints requires stringent monitoring and calibration. Skilled operators require training to manage printers complex material mixing and structural design checks. Supply chain limitations around local availability of specialised equipment or materials may also pose hurdles. Omani stakeholders tackle these issues by collaborating with international tech firms to establish training academies certification programs and onsite workshops. They also conduct repeated trial prints to refine material formulas and control settings under real world conditions building up local expertise step by step.

Human Impact: Empowering People and Communities

The impact of 3D printing in Oman extends beyond bricks mortar and machinery. It is about people families and communities. Faster housing delivery can alleviate shortages in remote towns relieving population pressure. Workers gain exposure to digital construction careers as operators technicians and robotics maintainers enabling skill diversification and upward mobility. Local entrepreneurs can launch businesses producing modular printed components or retrofitting printed units. Communities benefit from quieter cleaner construction sites with less dust noise and shorter timelines increasing public acceptance and participation. The technology supports inclusive growth by making built infrastructure accessible affordable and safer to all.

Building Public Private Partnerships

Oman is witnessing emerging collaborations between developers government agencies universities and global technology companies. Public private partnerships focus on scaling print operations co funding research pilot programs and launching innovation hubs. These hubs serve as centers for cross training experimentation and knowledge sharing. Government backing accelerates standardisation and regulatory clarity while private sector efficiency drives rapid adoption. This synergy is key to expanding beyond prototypes into mainstream development projects including affordable housing social infrastructure hospitality and temporary structures for events or tourism.

What the Future Holds

Over the coming years Oman is set to expand 3D printed infrastructure significantly. Future use cases include schools clinics tourist lodges emergency shelters and even pedestrian bridges using printed structural elements. Hybrid construction models may emerge that combine printed cores with traditional finishes or that integrate printed façade modules with steel frames. Centralised printing centers may produce structural kits delivered to remote sites speeding rural development. Local material production capabilities will grow meaning more printed mixtures use recycled aggregates gypsum or desert sands. As experience grows cost advantages improve public confidence technology standards stabilise and printed buildings become mainstream alternatives rather than pilot experiments.

Broader Economic and Community Benefits

As the technology matures Oman will benefit economically through reduced project costs faster execution and new industry formation. Training local talent builds human capital and reduces reliance on imported labor. Research initiatives position Oman as a hub for additive manufacturing expertise in the region potentially attracting global partnerships investment and exports. Printed structures designed for sustainability reduce operational energy needs and environmental impact. Communities gain access to quality resilient infrastructure delivered more rapidly. The result is a construction sector that is innovative efficient responsive and deeply aligned with national development goals.

Conclusion

The adoption of 3D printing in Oman’s construction sector signals a bold shift into an era of innovation human empowerment and sustainable progress. The advantages in speed efficiency cost savings design variety safety and environmental impact are transforming how buildings are conceived built and inhabited. As local material innovation academic research regulatory frameworks and industry collaborations expand the technology’s impact will scale. Most importantly this evolution hinges on people – workers learning new skills communities accessing safer affordable infrastructure and citizens witnessing the rise of buildings that are built faster smarter and kinder to the environment. Oman is not just printing structures it is building a brighter future based on human centered innovation resilience and sustainable growth.

Do follow Gulf Magazine on Instagram.

Also Read – Oman Women in Tech: Powerful Initiatives Driving Innovation and Progress