RFID Integration Boosts Qatar Asset Management with Powerful Efficiency Gains In Qatar’s bustling world of infrastructure, industry, and innovation, asset management is the quiet hero behind every smooth operation. Imagine trucks, equipment, and inventory that are never lost or even misplaced for long. That’s the reality RFID (Radio Frequency Identification) technology brings when integrated thoughtfully. This article explores how RFID tag integration is transforming asset management in Qatar, humanising the tech through stories of improved work life balance, time savings, and confidence in systems.

Understanding RFID and Why Qatar Needs It

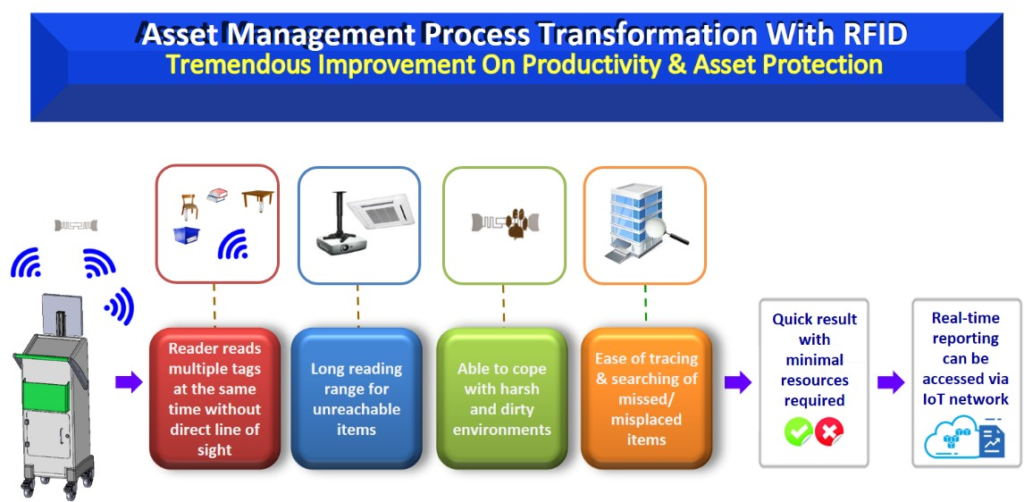

RFID tags are tiny wireless identifiers that can be attached to items such as vehicles, machinery, tools, even pallets. Instead of manually logging every item’s movement, RFID readers capture that data almost instantly. In Qatar, where large scale projects and government entities manage huge volumes of assets, manual tracking is both time intensive and error prone.

Moving to RFID gives businesses and agencies a single source of truth. Teams stop chasing spreadsheets and start trusting real time dashboards. That trust trickles down into smoother working days and less stress for staff who no longer worry whether a tool is lost or simply misplaced again.

How Integration Works The Human Touch behind the Tech

Mapping Assets and Choosing the Right Tags

First, organisations conduct a hands on workshop: front line staff, local operators, and managers walk assets, catalogue needs, and share stories about recurring pain points like misplaced tools, delays, or audit challenges. They then select RFID tags passive, active, or specialised based on location, durability, or distance needs.

Installing Readers and Calibration

Technicians work closely with onsite teams to install RFID readers in warehouses, yards, or loading zones. These placements account for human workflows such as entry exit paths, desks, loading bays. Calibration ensures tags register accurately without false positives so staff won’t be interrupted with constant alerts, but only see meaningful updates.

Training and Culture Shift

Rather than dumping technology, training sessions are interactive and employee led. Workers practice scanning, interpreting dashboards, and sharing tips with peers. The human focus builds confidence people see how much easier auditing or locating assets becomes. That trust is vital for long term adoption.

Key Benefits for Qatar’s Organizations and People

Streamlined Inventory and Reduced Loss

RFID integration drastically reduces time spent counting or chasing missing items. Inventory cycles that once took days can now complete in hours. That liberates staff to focus on high value tasks instead of tedious reconciliation.

Enhanced Security and Compliance

Sensitive or high value assets such as medical devices, construction machinery, or IT inventory get an extra layer of visibility. RFID logs every movement, creating an audit trail easily shared with regulators or stakeholders. Staff gain confidence knowing everything is tracked securely.

Real Time Analytics and Smarter Decisions

Managers receive dashboards showing usage patterns, idle assets, and predicted needs. Instead of reacting to shortages or undervaluation, teams can anticipate demand leading to smoother operations and more informed decisions.

Improved Employee Satisfaction

With manual inventory tasks minimised, employees feel empowered. They spend less time on repetitive tasks and more on meaningful work. Fewer interruptions, clearer data, and less frustration translate into happier teams and better retention.

Real World Use Cases in Qatar

Construction and Infrastructure Projects

Large construction firms in Qatar attach RFID tags to expensive equipment such as cranes, generators, and tools. When a project shifts sites, staff scan assets automatically, eliminating loss during relocation. By knowing exactly what’s where, operations run faster, and budgets stay on track.

Healthcare and Hospital Asset Tracking

Hospitals implement RFID tags on portable medical equipment like infusion pumps, ventilators, or wheelchairs. Nurses and technicians find what they need instantly reducing downtime in critical scenarios. Administrative teams also gain insights into utilization rates, improving planning and reducing unnecessary purchases.

Logistics and Warehousing

RFID transforms warehousing by enabling hands free scanning of pallets and cargo. Fast moving supply chains in Qatar especially those linked to ports or regional distribution centres see massive speed gains. Workers avoid manual bar code scanning or paperwork. They focus instead on quality control and oversight.

Overcoming Challenges Insights with a Human Touch

Addressing Privacy Concerns

Some staff may worry about constant tracking what data is captured, who sees it? Organisations address this through open conversation, explaining that RFID tracks assets, not people. Dashboards focus on tools and equipment, not staff movements. That transparency builds trust upfront.

Technical Limitations and Tag Durability

RFID tags can be sensitive to extreme heat or heavy machinery. Teams collaborate with vendors to choose ruggedized tags. During trials, staff report weak signals or downstream issues. That feedback leads to adjusted tag placement or reader range calibration making the system more reliable and human friendly.

Integration with Existing Systems

Many organisations already have ERP or inventory software in place. RFID solutions must integrate cleanly without forcing staff into new, unfamiliar workflows. By co designing with IT teams and operational staff, integration blends seamlessly, reducing friction and accelerating adoption.

What the Future Holds for Qatar

AI enhanced predictive asset analytics will soon leverage RFID data to forecast maintenance needs or replacement cycles. Technicians will get proactive alerts before a critical lever fails, reducing downtime and enhancing safety.

Mobile app integration enables workers to tap NFC enabled smartphones to read RFID tags no extra devices required. Teams in remote or off site work zones capture data easily while inspecting assets or reporting issues.

City wide infrastructure tracking could emerge, where public sector assets such as street sweepers, traffic sensors, or municipal tools are managed centrally via RFID and cloud platforms. That transparency fosters efficient services and responsive governance.

Final Thoughts People and Progress Hand in Hand

The story of RFID integration in Qatar isn’t just about cold technology it’s about empowering people to work smarter, safer, and with more confidence. Asset managers spot trends faster. Technicians lose less time locating tools. Leaders make decisions grounded in real time data.

More than a tracking system, RFID becomes a human centred bridge between organisation and operations delivering trust, clarity, and efficiency. Qatar’s forward looking entities are showing the world how thoughtful technology adoption can uplift both operations and the people behind them.

By choosing RFID with a human touch, Qatar is accelerating progress and ensuring that every asset, every person, and every process is aligned for excellence.

Do follow Gulf Magazine on Instagram.

Also Read – Carbon Capture Technologies Qatar: Pioneering Industrial Transformation with Innovation